How to Select the Right Extruder for PE Pipe Production: Diameter Matters

When planning a PE pipe production line, many customers start with a clear goal: they want to produce PE pipes.

However, one key detail is often still uncertain at the early stage — the pipe diameter range.

This situation is very common, especially for customers who are entering the pipe industry for the first time or expanding their existing product portfolio.

From an equipment selection perspective, pipe diameter is one of the most critical parameters.

Without a clearly defined diameter range, it becomes difficult to properly select the extruder model, design suitable dies, match the haul-off system, and ensure stable long-term operation of the entire production line.

In practice, unclear pipe diameter leads to unclear equipment selection.

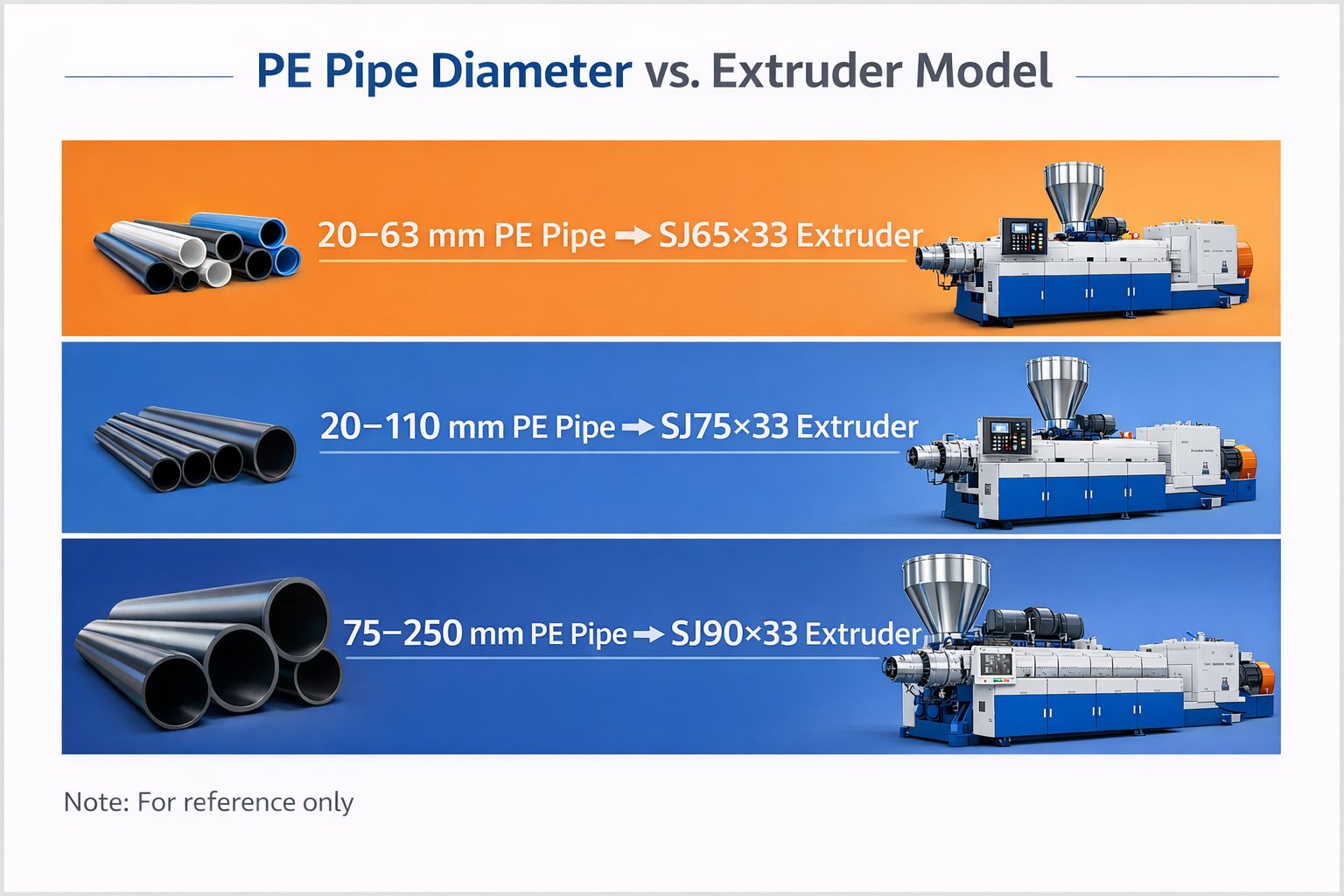

Typical Extruder Selection Based on PE Pipe Diameter

In the PE pipe industry, extruder models are usually matched according to the main pipe diameter range. Below are common configuration references used in many projects:

20–63 mm PE pipes

This diameter range is typically produced using an SJ65×33 single screw extruder.

It is suitable for small-diameter water supply pipes and electrical conduits. The equipment offers good flexibility, easier specification changes, and relatively controlled investment costs.

20–110 mm PE pipes

For this range, an SJ75×33 single screw extruder is commonly used.

This is one of the most popular diameter ranges in the market, as it provides a good balance between output capacity, energy efficiency, and production stability.

75–250 mm PE pipes

This range usually requires an SJ90×33 single screw extruder.

Larger diameters demand higher extrusion output, better melt stability, and more precise coordination of the downstream equipment. Such configurations are more suitable for customers with clear market positioning or project-based orders.

Why Defining Pipe Diameter First Improves Project Efficiency

Based on real project experience, once customers clearly define their main target pipe diameters, the entire equipment solution becomes much more straightforward.

Communication becomes more efficient, technical proposals are more accurate, and the risk of over- or under-investment is significantly reduced.

It is important to note that equipment selection is not about choosing the largest extruder, but about selecting the most suitable configuration for the target products, market demand, and investment plan.

Conclusion

For anyone planning a PE pipe production line, a simple but essential step should come first:

clearly define the pipe diameter range you intend to produce.

This decision will directly determine the extruder model, line configuration, and overall project success.