Unveiling the Three Key Technologies Behind a High-Efficiency PE Pipe Extrusion Line

In the plastic pipe manufacturing industry, a high-performance PE pipe extrusion line means more than just faster production — it represents product consistency, energy efficiency, and long-term reliability.

So, how does a PE pipe production line achieve stable and continuous extrusion? Let’s explore the three core technologies that make it possible.

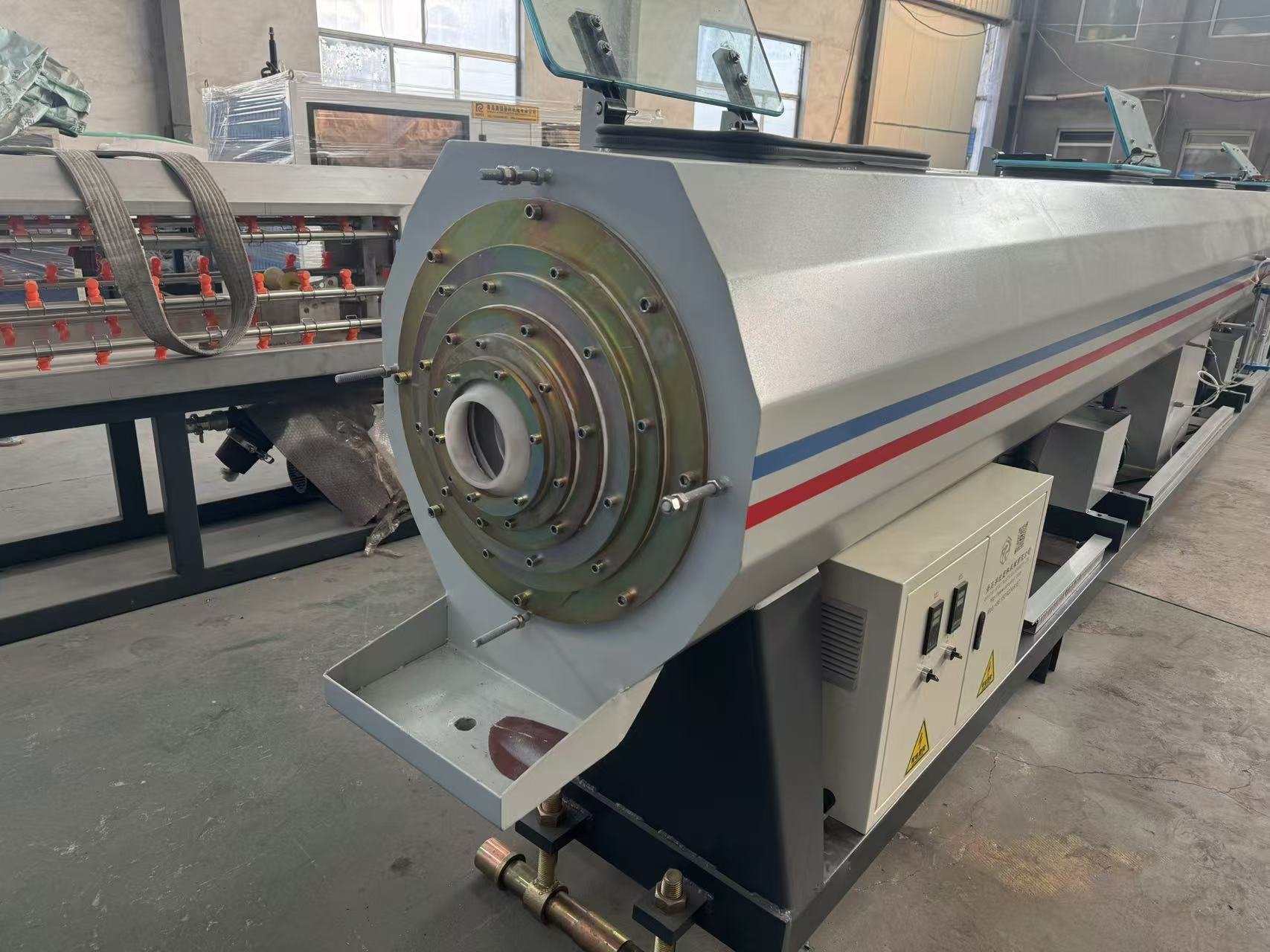

1. Precision Extruder Design – The Heart of Stable Extrusion

The extruder is the core of the entire production line. Our PE pipe extruder adopts an advanced, energy-saving screw design that ensures uniform plasticization and stable melt flow.

This prevents defects such as bubbles or uneven wall thickness, guaranteeing smooth and consistent extrusion.

Equipped with a frequency conversion control system, the extruder automatically adjusts the screw speed according to pipe size, achieving precise control and higher energy efficiency.

2. Vacuum Calibration and Cooling System – Ensuring Dimensional Accuracy

After extrusion, the pipe enters the vacuum calibration tank — a critical step in achieving precise sizing.

Our vacuum tank uses a multi-point vacuum calibration system to help the pipe quickly form and maintain roundness. Combined with multi-stage water spray cooling, the system effectively controls shrinkage and ensures uniform pipe diameter and wall thickness.

Stable sizing and efficient cooling guarantee that every PE pipe meets strict quality standards.

3. Intelligent Haul-Off and Cutting System – Precision in Every Meter

The haul-off unit maintains a constant pulling speed that matches the extrusion speed, preventing deformation during production.

The automatic cutting unit is equipped with a length-measuring system for accurate and clean cuts. It works in full synchronization with the entire line to ensure smooth pipe ends and consistent lengths.

All major parameters can be controlled through a touch screen interface, making operation simple, efficient, and reliable.

Stable Production, Reliable Quality

With advanced extrusion design, precision calibration, and intelligent control systems, our PE pipe extrusion lines ensure 24-hour continuous operation with high output and stable performance.

The produced PE pipes are widely used in water supply, electrical conduit, drainage, and industrial piping applications.

At Qingdao Aorui Plastic Machinery Co., Ltd., we believe that stable machines build reliable partnerships. We will continue to innovate and provide our global customers with high-efficiency and energy-saving plastic pipe extrusion solutions.